The heart of the EBRO project beats strongly

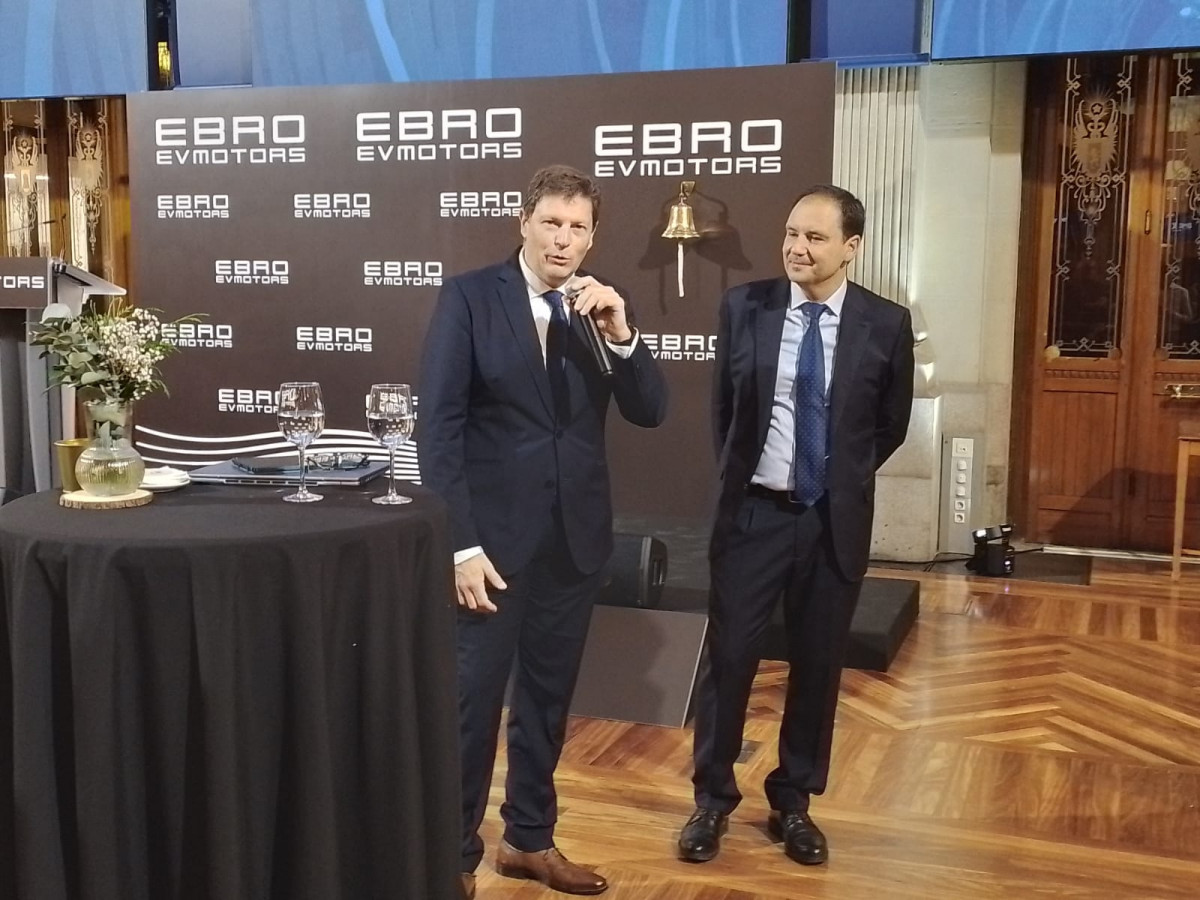

The revival of a brand with more than 70 years of history, with an image of reliability and efficiency that still survives in the Spanish automotive imagination, has culminated in a unique project. Rafael Ruiz, President of EV Motors-EBRO and Pedro Calef, President of EBRO SUV, discuss the details of the brand's industrial comeback. Report published in AutoRevista 2.398

The robustness of the EBRO brand, modernised in terms of design, innovation and safety, is a hallmark that will also be reflected in the industrial project, initially for assembly, in Barcelona's Zona Franca. Manufacturing operations began last November. Rafael Ruiz, president of EV Motors-EBRO, and Pedro Calef, president of EBRO SUV, agree that ‘the start-up of the activity is going very well, as planned. It is a line with different stages of assembly of components in the vehicle, which currently employs more than 120 people per shift. Right now we have two shifts, but by the end of this semester we hope to add a third shift. The planned supply flow of materials and components from the current assembly line allows us to generate an output of six vehicles per hour.

The aim is to complete the line's three-shift cadence to produce around 130 cars per day

The goal, as we said, is to complete the line's three-shift cadence for the production of about 130 cars per day’. The forecasts for integrating the welding and painting operations at the EBRO Factory, a plant of more than 250,000 square metres, are ‘between the end of this year and the beginning of next year’, according to both executives.

Regarding expectations of demand in Spain with a view to occupying the plant's capacity for as long as possible, Ruiz and Calef comment that ‘our medium-term objective in Spain is to reach 30,000 vehicles per year as soon as possible. We started sales last December and we are having a very good reception of our two models S700 and S800’. The arrival of new models from the brand could materialise throughout 2025, while the Omoda 5 is expected to arrive in the second half of the year. ‘It will be announced when the dates are finalised,’ say Ruiz and Calef.

We have started sales last December and we are having a very good reception of our two models S700 and S800

The managers state that ‘the revitalisation of the Zona Franca plant's activity is, in fact, the heart of the EBRO project: returning industrial activity to the plant, manufacturing vehicles again, recovering employment, bringing this activity to the supplier park as well... this is the basis of our project to get the EBRO brand rolling again throughout Spain. To this end, more than 700 people have already been reinstated from the previous stage. The role of the Generalitat and the Ministry of Industry has been key. We have all worked together to make the reindustrialisation of Zona Franca a reality’. Those responsible for the EBRO industrial project are already in talks with local suppliers. ‘Our aim is for the local ancillary industry to regain opportunities with us’.

Our aim is to bring the local ancillary industry back into opportunities with us

In terms of involvement in the sector's organisations, Rafael Ruiz and Pedro Calef are very positive about their membership of ANFAC. ‘We are grateful to ANFAC for belonging to the manufacturers' association, because it brings together all the historical knowledge of all the brands that have manufactured in Spain over many years. We are just starting out, but we believe that we will also be able to contribute value to the association. In the case of the Clúster d'Automoció de Catalunya, CIAC, the EV MOTORS group, our parent company, is already associated with CIAC. Our will is to continue collaborating’.

R+D+i

Regarding the creation of a technical and R&D centre and how it would collaborate with similar entities at Chery, Rafael Ruiz and Pedro Calef clarify that ‘we are not considering it as a question of deadlines. Currently, our company already has an important R&D department for the development of EBRO models. We see a magnificent opportunity to attract qualified talent and place Barcelona on the world map of technical centres. With our partner, we would bring another important qualitative asset to the automotive sector, in the city and in the country. In the end, this translates into reinforcing our industrial fabric’.

We see a great opportunity to attract qualified talent and put Barcelona on the world map of technical centres

With a total workforce of 700 people and an estimated investment of more than 300 million euros for the entire EBRO project, EV Motors-EBRO began trading on the stock exchange last November. ‘The experience is going very well. We have full confidence in our project - of course - but now we know that many other people do too. We have exceeded expectations: we exceeded 20% of the initial price of the stock and we are close to €400m in capitalisation. We have been a success story for BME Growth in 2024. We are very proud and also very grateful to all those who believe in our company and in our project. We want to make it grow and grow together, and going public is part of gaining speed to do so.

EQUIP AUTO París 2025 celebrará su 50º aniversario, con el patrocinio de Emmanuel Macron, presidente de la República francesa, con una edición histórica y festiva. Del 14 al 18 de octubre de 2025, en Paris Expo Porte de Versailles, la feria congregará a más de 1.400 expositores y marcas en 100.000 m² y espera la asistencia de 100.000 profesionales.

El Centro Tecnológico de la Energía (ITE) es un referente en campos de investigación claves en la actual transformación de la movilidad, como nos explica María Porcel, responsable de línea I+D de materiales para hidrógeno de ITE.

CUPRA ha renovado sus modelos Formentor, León y León Sportstourer, combinando un diseño atrevido con tecnología inteligente y de vanguardia. Las últimas novedades incluyen la avanzada iluminación Matrix LED Ultra, una mayor ayuda a la conducción gracias al asistente de tráfico cruzado delantero, y el nuevo color de carrocería Dark Void.

ASEPA ha presentado la nueva línea editorial de sus publicaciones con la creación del ‘Observatorio EVomarket’, que tiene como objetivo ofrecer a todos los profesionales de la automoción una información clara y rigurosa de la evolución del mercado de los vehículos electrificados en España vs. Europa.

Pirelli ha lanzado al mercado un neumático producido con más del 70% de materiales de origen natural y reciclado, entre los que se incluye caucho natural certificado por FSC (Forest Stewardship Council).