Silence consolidates the industrial project in the Zona Franca of Barcelona

With a well-established position in the manufacture of electric motorbikes, Silence Acciona Mobility has taken a step forward with the production of the S04 nanocar. We spoke to Josep Mariné i de Clara, Executive Director of Operations, to learn about the recent transformation of the manufacturing facilities in Barcelona's Zona Franca. Report published in AutoRevista 2.399. Lea este reportaje en castellano.

Josep Mariné explains that ‘we have been working on series production since the end of September and although, as with any launch, it has taken a while, we have reached a smooth pace of car deliveries’. When it comes to tackling a project of these characteristics, an electric microcar like the Silence 04 nanocar, Mariné stresses that ‘in addition to the quality that goes without saying, the fundamental factor is the cost. It is a smaller car and, therefore, it has to cost considerably less than a conventional one. That said, after receiving the parts from the suppliers, we carry out the processes of welding the structure of the car and painting it to protect it against corrosion. The welded and painted structure goes to the assembly line where the rest of the stamping parts, the cockpit, wheels... are assembled until we reach the finished product. We assemble parts that are already tested, subjected to a large number of tests, and then we also carry out tests on finished vehicles to guarantee the quality of the entire production’.

The Silence Acciona Mobility plant is prepared to manufacture ‘a capacity of 20,000 units of the S04 nanocar in one shift. Regarding the extrapolation of experience in the manufacture of electric motorbikes to four-wheeled vehicles, Mariné confesses that ‘they are very different processes. The manufacturing line is shorter with a simpler process than that of a nanocar which, without being a conventional car, requires much more elaborate work. We have benefited from the experience of a dedicated and hard-working team who have been highly motivated to work on the new product. The motorbikes and the nanocar are produced on separate lines that share space in the factory”.

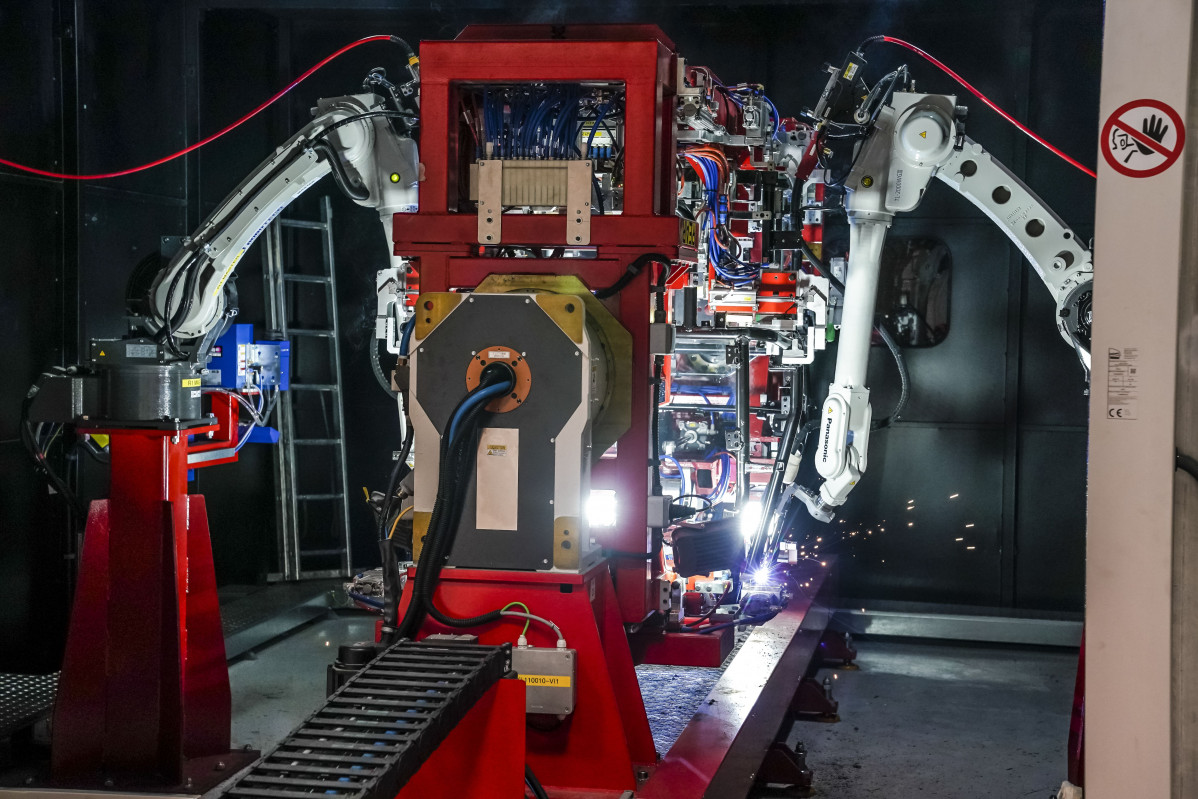

For manufacturing operations, Mariné highlights the functionality of robotics in welding, ‘which is very common in this type of process’, and in terms of development tools, he emphasises the design phase in which ‘we have tools such as 3D glasses and spaces to interact with the car virtually. In the engineering phase, we work with the digital mock-up (DMU), which allows us to correct and advance the design of components without the need for physical prototypes. We are currently working to incorporate a digital PLM (Product Lifecycle Management) platform, which ‘will allow us in the near future to work with the digital twins and project it in other areas of the company such as after-sales or spare parts, which will give us a plus’.

The plant has a battery manufacturing line, next to the vehicle manufacturing lines. Mariné explains that ‘we acquire the components, subject them to quality controls and assemble them to supply them to both the vehicle assembly lines and the Battery Stations. We currently have two approved battery suppliers and we are working with another two with a view to their approval and thus be able to count on a greater number of suppliers’.

International projection

With regard to the marketing of the products manufactured at the Silence plant in Barcelona's Zona Franca, Josep Mariné comments that ‘as far as motorbikes are concerned, we are number one in sales of electric 125 scooters, and as far as nanocar is concerned, the recent agreement signed with Nissan has enabled us to take an important step forward in terms of product internationalisation. With Nissan, we are projecting ourselves in France, Italy and Germany, and we are about to open the English market. In Spain and Portugal, we do the marketing ourselves, with dealers and flagship stores in the main Spanish cities, with plans to open more. Also on the international side, we are expanding the Battery Stations, the battery recharging points, a point of differentiation in our presence with respect to our competitors in the market. This is the possibility of changing the battery in 30 seconds at a point where we already have a very considerable presence in Spain and we are working to grow in France, Germany and Italy, where, as I said, we go hand in hand with Nissan. We are investing heavily to implement Battery Stations at European level, while growth continues in Spain’.

Electrification and micro-mobility

Josep Mariné refers to Silence's business plan, commenting that ‘we believe that the future lies in electrification and, above all, in micro-mobility, which is the market where we feel strong. It is about mobility in cities or populated areas that are relatively close to large cities. Recently, the Barcelona Chamber of Commerce pointed out that 90% of the people who travel in Barcelona do not move more than nine kilometres. A nanocar has 150 km of local autonomy, which makes it very suitable for this type of mobility. Furthermore, according to the same source, 75% of these people who travel in large cities such as Barcelona, Madrid or Seville travel alone, which means they need small cars. This is where we see the future of micro-mobility, and if we add to this the ease with which we can change the battery, solving what is currently holding back electrification to some extent - charging - we are convinced that we have an important market there’.

Suppliers

Returning to the industrial area, Josep Mariné comments on supplier management, indicating that ‘we try to locate as many supplies as possible close by for reasons of cost and proximity when it comes to resolving possible incidents. However, we do have suppliers located further afield, most of whom are Chinese. We are increasingly promoting a greater local presence, with suppliers in Spain, with the idea of continuing to grow in this sense’.

Regarding the period prior to the establishment of Silence at its current facilities in Barcelona's Zona Franca, the executive director of Operations refers to ‘the commitment to hire 50% of the staff that would have previously belonged to the Nissan factory's workforce, with the idea of giving preference to unemployed former Nissan workers. So we have solved an existing problem and we are very happy with the results”.

Upcoming launches

Last November, Silence unveiled its first motorbike with off-road capabilities, the S05 Weekender, at the International Exhibition of Bicycles, Motorcycles and Accessories (EICMA), held in Milan from 7 to 10 November. The S05 Weekender is a vehicle suitable for everyday urban use and at the same time capable of making small forays on trails, the S02 scooter - a more robust, lighter and more manoeuvrable evolution - and the prototype of a third bike in the grand touring scooter category, the GT-SX Prototype, which will have more autonomy and power designed for intercity rides.

On the product level, Mariné points out that ‘this year we will certainly launch a new bike and there is a good chance of launching a second one at the end of the year. We will launch the S02 around June or July of this year and it is possible that at the end of the year or early 2026, we will launch the Silence GT, a revolutionary model for us because we will leave the 125 sector and move into the 350 or 400 segment. It will be a bike with two batteries, a very high range and greater acceleration. So, a bigger bike, with two batteries and almost all the features multiplied by two. At EICMA in Milan we presented the first prototypes of the S02 and another bike, the S05 Weekender. In a year and a half, we intend to launch three bikes, two for sure and one very likely’.

Industry Live acogió, el 19 de junio, una mesa redonda sobre el hub en España con la participación de ANFAC, Gestamp, Mondragon, SERNAUTO y T-Systems.

Nissan ha anunciado que planea transferir e integrar la producción de vehículos en la planta de Oppama, situada en el distrito de Oppama, a Nissan Motor Kyushu en la prefectura de Fukuoka, como parte de su reestructuración global de la producción bajo su plan de recuperación Re:Nissan.

EQUIP AUTO París 2025 celebrará su 50º aniversario, con el patrocinio de Emmanuel Macron, presidente de la República francesa, con una edición histórica y festiva. Del 14 al 18 de octubre de 2025, en Paris Expo Porte de Versailles, la feria congregará a más de 1.400 expositores y marcas en 100.000 m² y espera la asistencia de 100.000 profesionales.

El Centro Tecnológico de la Energía (ITE) es un referente en campos de investigación claves en la actual transformación de la movilidad, como nos explica María Porcel, responsable de línea I+D de materiales para hidrógeno de ITE.

CUPRA ha renovado sus modelos Formentor, León y León Sportstourer, combinando un diseño atrevido con tecnología inteligente y de vanguardia. Las últimas novedades incluyen la avanzada iluminación Matrix LED Ultra, una mayor ayuda a la conducción gracias al asistente de tráfico cruzado delantero, y el nuevo color de carrocería Dark Void.