Mariluz Villamor (BAM): ‘We are convinced of achieving a competitive advantage and accelerating the technological-digital transformation’

At the end of 2023, the creation of a new centre called to be a benchmark in advanced manufacturing technologies for the automotive industry was announced. The Basque Automotive Manufacturing Center (BAM) was created as a technology testing centre and a favourable framework for high-level collaborative innovation, whose avant-garde headquarters will be operational by the end of 2025. Its CEO, Mariluz Villamor, tells us about it.

AutoRevista.- The BAM was born from the initiative of Mercedes-Benz, Gestamp and Mondragón, together with the Basque Government. How did the idea of these three large companies come about and what are the main aspirations when creating the entity? How has the Government of the Basque Country become involved and how do you think the project can increase competitiveness in the territory?

Mariluz Villamor.- The idea arose from the need to develop excellent research to overcome the challenges of electrification, sustainability and digitalisation in the Basque automotive sector. We value very positively that the three founding partners of the BAM are three leading companies in the automotive sector in Alava and the Basque Country (Mercedes-Benz, Gestamp and the Mondragón Group through MB Sistemas), as it represents a very important strategic commitment to this advanced automotive manufacturing centre.

The aspiration was, based on the existing capacities in a key sector for the Basque Country such as the automotive industry, to provide the Historical Territory of Alava (where the Mercedes-Benz España van plant is located) with an advanced research centre with a cutting-edge scientific-technological infrastructure and to promote public-private collaboration between companies, technological agents and the administration.

The involvement of both the Basque Government and the Provincial Council of Alava has been maximum, which is why we are convinced that the objectives of increasing the competitive advantage and accelerating the technological-digital transformation in the Basque automotive sector will be achieved.

AR.- It can be said that we are still in the gestation phase and that take-off will take place in 2025, how will the next steps materialise?

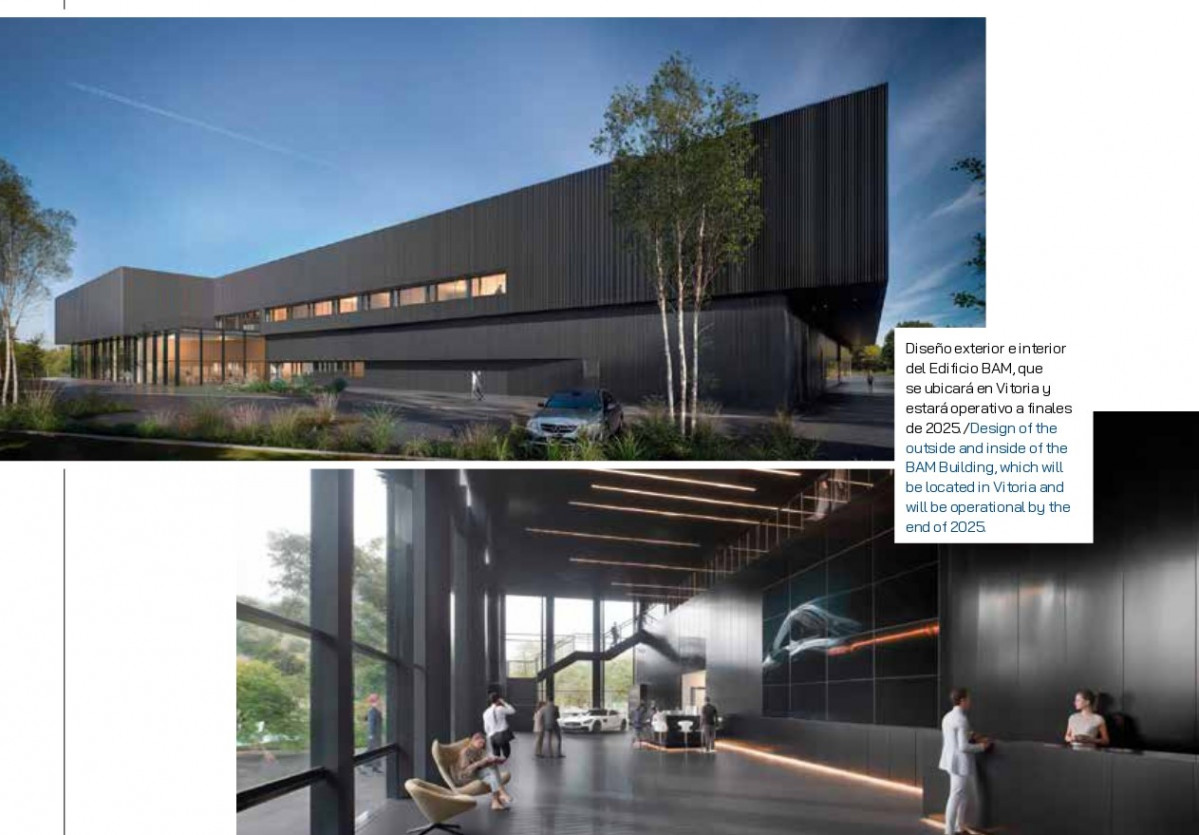

M.V.- The start-up of BAM is already a reality and we are already in the process of acquiring the scientific-technological equipment from January 2024. The location of this equipment will be in a provisional space until the new building is available at the end of 2025 and it will be then that the equipment acquired will be moved to the new laboratory spaces.

The BAM Building will have a unique ad-hoc design for the development of each area of research, as well as an area for the BAM Academy to provide specialised training and to carry out internships for the Master's degrees organised in collaboration with universities in the Basque Country. Each of these research areas will have a specific, tailor-made design for carrying out research projects and will also have the necessary scientific and technological equipment.

The earthworks have already begun and at the moment the plan for the dates awarded to the construction company UTE is on schedule.

AR.- The BAM was born from the automotive sector, but with a vocation to expand into other industries and activities, how is this multi-sectoral character going to take shape?

M.V.- We want to focus in the first few years on companies in the Basque automotive sector and then we will gradually expand to other industries such as mobility and sustainability.

The incorporation of new members belonging to the automotive sector will take place from January 2025 and the membership model will be announced in the coming months. We have recently shared with Miren Bilbao, director of the Miñano Technology Park, the areas where we are developing innovation ideas with the idea of looking at which companies we will develop these projects with in 2025.

With regard to mobility, we have participated from 24 to 26.9 in a stand shared with Mobility Lab at the S-Moving Greencities fair in Malaga to promote a network of contacts in this sector. With regard to sustainability, in June we established a first contact with Iberdrola's sustainability innovation area, where we talked about setting up joint technology conferences in 2025 and establishing collaboration channels between BAM members and Iberdrola, as a first step.

AR.- In which technologies does BAM aim to be an advanced centre, and in which fields of digitisation and software will it have the greatest impact?

M.V.- BAM has established the following areas of research and technological development:

- Advanced and intelligent manufacturing. Lines of research and development will be developed in several of the main areas of the electric vehicle.

In the first area, we are investing in flexible research teams capable of addressing new knowledge in the form of joining technologies such as the thermal joining of steels and aluminium, the mechanics of hybrid materials, laser or adhesives, among others. In terms of logistics and vision, we will have new AGV technologies with LCA trolleys and tools or vision systems integrated in installations (Bin Picking for robot guidance, smart cameras, etc.), which incorporate new knowledge in the form of intelligent systems that are capable of self-management.

For the development of new surface finishing technologies, investment is being made in robots for the automation of sealing, polishing, etc., linked to the surface control of defects by applying artificial vision and Machine Learning.

- Digital manufacturing. The technologies included in this area of BAM are multiple, and include aspects such as artificial vision, digital twins, cybersecurity, virtual and augmented reality, new electronic architecture of the vehicle, etc.

- Test-Lab,. For software testing, for example, and also workstations for virtual commisioning and digital process twins.

AR.- How do you plan to collaborate with other entities in the short and medium term (technology centres, universities, associations, clusters, start-ups, etc.)?

M.V.- We have already launched training activities in new technologies and digitalisation for current partners. In addition, BRTA companies (such as Tecnalia or Vicomtech) have been contacted for the first innovations that are being developed within the strategic working groups of the BAM. On 13.9 we signed an agreement with the University of Mondragon for the first PhD student at BAM.

We are preparing to launch a new master’s degree in advanced automotive manufacturing technologies, which is expected to start in September 2025 in collaboration with the UPV-Escuela de Ingeniería de Alava. In this Master's Degree, more than half of the teaching staff will be automotive professionals selected from BAM for their experience in Advanced Robotics, Data Management and application of AI in Automotive, Additive Manufacturing, Lean Manufacturing, etc. The internships for this master's degree will be mainly at BAM or its partners. Finally, we are in contact with the Automotive Committee of the AEC, of which I am a member, to organise a Technology Conference on practical cases of Industry 4.0 in the Automotive sector in January 2025.

AR.- Will one of the objectives be to participate in European and international projects with similar entities in consortiums or joint projects?

M.V.- We have the medium-term objective of collaborating with other consortiums similar to BAM at both national and international level:

- national level (we made a first contact in March with the CFAA of the Aeronautics sector and in April with the CTAG in April where we talked about possible collaborations in the field of software testing).

- as well as at an international level in a second phase still to be defined, in which entities similar to the AMRC of the University of Sheffield (United Kingdom) or the Ford Advanced Manufacturing Centre in Detroit (United States) fit in.

AR.- Will BAM try to promote the development of professional profiles, as well as to attract and retain talent in the current difficult situation in this area?

M.V.- The two main areas that constitute BAM's training axis for attracting and retaining talent in the Basque Country are:

- - Training ‘in what is not available’ with the aim of raising the current level. In this sense, BAM plans to become a centre of new knowledge with the aim of transferring it to the sector.

- - Training ‘in what there is’ with the aim of structuring it and increasing its impact. BAM aims to become the reference centre for advanced manufacturing technologies in the electrification of the automotive sector. The aim is that BAM can integrate all the agents that currently have knowledge in a field related to the activity developed in the Centre and between all of them contribute to the objective of being a European benchmark and therefore promote the development of professional profiles.

In what way? Well, among the activities planned to be developed by BAM Academy are:

- Master's programmes in English

- Specific training programmes in advanced manufacturing technologies in the automotive industry and digitalisation.

- Doctorate programmes.

- Dual training programmes.

With all this we will attract international talent and we hope to retain it with attractive job offers in the automotive industry in the Basque Country.

Lea esta entrevista en castellano

Industry Live acogió, el 19 de junio, una mesa redonda sobre el hub en España con la participación de ANFAC, Gestamp, Mondragon, SERNAUTO y T-Systems.

Omron ha sido premiada con el iF Design Award 2025 por su nuevo centro de automatización de Stuttgart (Alemania). El galardón, presentado por el iF International Forum Design, destaca el cuidado diseño del centro de automatización y su contribución a la innovación industrial colaborativa.

Nissan ha anunciado que planea transferir e integrar la producción de vehículos en la planta de Oppama, situada en el distrito de Oppama, a Nissan Motor Kyushu en la prefectura de Fukuoka, como parte de su reestructuración global de la producción bajo su plan de recuperación Re:Nissan.

EQUIP AUTO París 2025 celebrará su 50º aniversario, con el patrocinio de Emmanuel Macron, presidente de la República francesa, con una edición histórica y festiva. Del 14 al 18 de octubre de 2025, en Paris Expo Porte de Versailles, la feria congregará a más de 1.400 expositores y marcas en 100.000 m² y espera la asistencia de 100.000 profesionales.

El Centro Tecnológico de la Energía (ITE) es un referente en campos de investigación claves en la actual transformación de la movilidad, como nos explica María Porcel, responsable de línea I+D de materiales para hidrógeno de ITE.