Michael Boe (BorgWarner): "We aim to bring cutting-edge OE technology to the aftermarket space"

AutoRevista.- Our magazine AutoRevista is focused on OE, but it is interesting to get the aftermarket point of view. How is BorgWarner tackling the automotive trends bringing them to the aftermarket business?

Michael Boe.- BorgWarner's approach to the aftermarket is deeply aligned with the latest automotive trends, including electrification, emissions reduction, and enhanced vehicle performance. We aim to bring cutting-edge OE technology to the aftermarket space, ensuring that our customers have access to high-quality, advanced solutions that meet the evolving demands of the industry.

The aftermarket business is a critical aspect of BorgWarner’s overall strategy

We have a leading product portfolio consisting of turbocharger technologies, ignition products, fan and fan drives as well as exhaust gas management systems. This includes expanding our product range with innovative components such as mechatronic modules for dual clutches, timing chains, friction plates, and inverters. The aftermarket business is a critical aspect of BorgWarner’s overall strategy. It allows us to support the lifecycle of vehicles with state-of-the-art products, maintaining our commitment to performance, quality, and sustainability.

AR.- What are the most oustanding BorgWarner's features in Automechanika and how is the importance of aftermarket business in Europe and, particularly, in Spain?

M.B.- .- At Automechanika Frankfurt 2024, BorgWarner is showcasing an expanded lineup of products, including our latest additions such as timing chains, friction plates, mechatronic modules, and inverters, as well as our market-leading turbochargers, EGR valves, ignition technologies, and advanced transmission solutions. This will be our first appearance featuring our new company logo and updated packaging, reinforcing our commitment to innovation and sustainability.

The European market, including Spain, is characterized by a high demand for quality and performance, making it essential for us to continuously innovate and adapt

The aftermarket business is highly significant for BorgWarner, particularly in Europe, where it plays a vital role in our growth strategy. The European market, including Spain, is characterized by a high demand for quality and performance, making it essential for us to continuously innovate and adapt. In Spain, where the vehicle fleet is diverse and aging, our advanced solutions provide the reliability and efficiency that our customers require, supporting our strong market position. We have invested in a team in Spain, adding service ability during 2024. We have high expectations for continuous success in the Spanish market.

AR.- What is the focus of the new brand corporate logo and what are the messages you want to send to the industry with this image?

M.B.- The evolution of our corporate logo reflects BorgWarner's ongoing transformation and forward-looking vision. It symbolizes our commitment to innovation, sustainability, and leadership in the automotive industry. The modernized logo is designed to convey a sense of movement and progress, aligning with our mission to drive cleaner and more efficient mobility solutions. Through this refreshed image, we aim to reinforce our dedication to excellence and our proactive approach to the future of automotive technologies, whether in the OE or aftermarket sectors.

The modernized logo is designed to convey a sense of movement and progress

AR.- It seems electrification speed is not developing as fast as thought. In what way is BorgWarner working high efficiency ICE solutions and hybrid parallel to electric vehicles systems and modules?

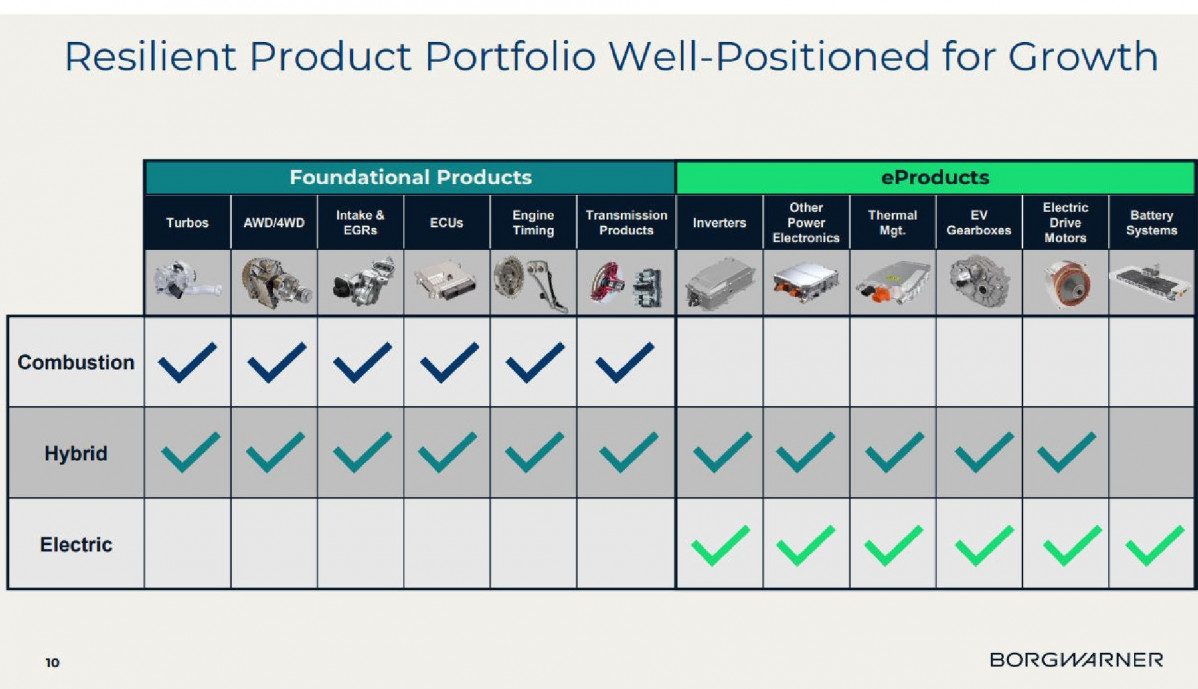

M.B.- BorgWarner recognizes that the path to full electrification will take time, and we are committed to supporting all facets of the transition. While we continue to innovate in the electric vehicle space, we are also heavily invested in optimizing internal combustion engine (ICE) technologies and hybrid systems to improve efficiency and reduce emissions.

We believe that by offering high-efficiency solutions across all propulsion types, we can support a balanced and flexible approach to the industry's transformation

Our advanced turbocharger solutions, EGR valves, and thermal management products are just a few examples of how we are enhancing the performance and sustainability of ICE and hybrid vehicles. We believe that by offering high-efficiency solutions across all propulsion types, we can support a balanced and flexible approach to the industry's transformation.

AR.- This year, BorgWarner has established a partnership with Manufacture 2030 in one example about sustainability as a main vector in the company strategy. How is working on sustainability both OE and aftermarket and which could be next steps in the medium term?

M.B.- Sustainability is at the core of BorgWarner’s strategy across both OE and aftermarket sectors. Our partnership with Manufacture 2030 underscores our commitment to reducing our environmental footprint, focusing on lowering emissions, waste, and energy consumption, also together with our suppliers. In the aftermarket, we are actively working to reduce the impact of our products by remanufacturing components like turbochargers and EGR valves, thus extending their lifecycle and minimizing waste. Additionally, our European Aftermarket headquarters in Germany has a set up with our logistic partners since 2021, so we can make sure to have carbon-neutral product transportation and shipments.

Our partnership with Manufacture 2030 underscores our commitment to reducing our environmental footprint

Looking ahead, we will continue to explore further opportunities in circular economy practices, sustainable packaging solutions, and new technologies that reduce environmental impact, ensuring that our sustainability efforts remain at the forefront of our industry.

AR.- Chinese OEMs are growing in European market, even with their own manufacturing plants. What opportunity can bring this trend for BorgWarner?

M.B.- At BorgWarner we are partnering with all major OEMs in the world. No matter where OEMs decide to set up their footprint, we’re already there. We have a great relationship with our Chinese customers. If they decide to start manufacturing in Europe, we can still deliver them with our products.

AutoRevista analiza el informe ‘Movilidad Eléctrica en España. Situación actual, objetivos y retos a abordar’ de May López, profesora de OBS Business School, que concluye que la movilidad eléctrica se posiciona como pieza fundamental en las estrategias de sostenibilidad.

Una información de Irene Díaz.

La infraestructura de recarga de acceso público en España sigue desarrollándose a buen ritmo. Según el Barómetro de Electromovilidad de ANFAC, durante el segundo trimestre de 2025, la red de recarga ha aumentado un 3%, con 1.534 nuevos puntos instalados.

ACICAE-Cluster de Automoción del País Vasco ha entregado los XIX Premios Automoción-ACICAE 2024 a personas organizaciones y proyectos que han destacado por su labor en favor de la competitividad del sector de automoción.

Toyota España ha vuelto a destacar su apuesta por el hidrógeno como energía sostenible, limpia y respetuosa con el medio ambiente participando en la duodécima edición del Green Gas Mobility Summit, celebrada los días 25 y 26 de junio en La Nave (Madrid).

Para celebrar su 70 aniversario, Alpine ha creado una película de tres minutos que repasa los momentos más destacados de su historia y los que están por venir. El vídeo pone música a la visión del fundador de Alpine, Jean Rédélé, y al lema de la marca: ‘Convertir la ligereza en una fortaleza’.